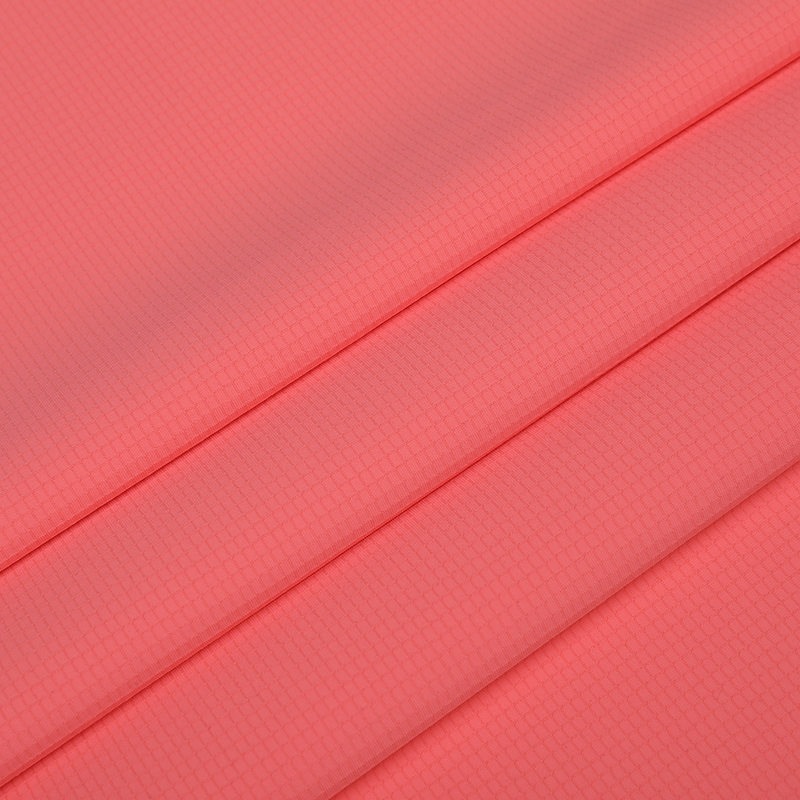

APJ1016 Warp knitted jacquard nanomeg polyester ammonia knitted fabric

APJ1016 warp knitted jacquard nanolattice polyurethane knitted fabric adopts precision warp knitting jacquard technology, and achieves fine weaving of nanolattice patterns through high-precision machinery and complex programming control. This pattern design not only shows a unique visual effect, but also reflects our profound accumulation in weaving technology. At the same time, we cleverly combine the use of semi-gloss and matte yarns to give the fabric rich layering and light and shadow changes to meet different design needs. APJ1016 uses N50D/12F polyester and spandex as the main raw materials, and ensures the comprehensive performance of the fabric through scientific proportioning. The addition of polyester significantly improves the wear resistance, wrinkle resistance and stiffness of the fabric, while the appropriate addition of spandex gives the fabric elasticity and recovery, ensuring comfort and fit. We also specially introduced the OP40D ingredient to further enhance the softness and skin-friendliness of the fabric and enhance the wearing experience. Advanced nanotechnology is used to treat fabrics to effectively improve the anti-fouling and antibacterial properties of the fabric, extend the service life of the product, and at the same time protect the health and safety of the wearer. The unique fiber structure ensures that the fabric has good breathability, can quickly discharge sweat and moisture, keep the skin dry and comfortable, and is suitable for wearing in various climate conditions. The fabric treated with a special process has dimensional stability and can maintain its original shape and size even after long-term wear or frequent washing, extending the wearing life of the garment. APJ1016 warp knitted jacquard nanogrid polyester-polyester knitted fabric is suitable for high-end fashion women's wear, men's casual wear, sportswear, home textiles and other fields.

1. Polyester fiber fabric has better stiffness than other materials (such as cotton, nylon, etc.).

2. Polyester fabrics are known for their unique elasticity and comfort, and this fabric does not rely on spandex to achieve elasticity.

3. Mechanical elastic fabric can produce a large retraction force when stretched, and maintain the original flat, fluffy and crisp state.

4. Polyester fiber fabric has waterproof performance and fast drying effect, and it is often used as the main ingredient in outdoor sports clothing.

5. Elastic fabrics are more suitable for fitness wear, running wear and dancewear than other ordinary fabrics or chemical fiber fabrics, but also require support and tight degree of demand for high scenes.

6. elastic fabric also has good moisture absorption and quick drying performance. Its double helix structure presents an eight-figure groove section, and its moisture absorption and quick drying property is 8 times higher than that of cotton and two times higher than that of ordinary polyester. This characteristic makes mechanical elastic fabric one of the ideal casual wear main fabrics, to meet the market demand for fast moisture absorption and rapid drying.

7. Under the background of environmental protection becoming a new pursuit, elastic fabric has overcome many shortcomings of spandex elastic fabric and become one of the main choice of casual wear fabrics. Its ammonia-free properties not only reduce environmental pollution, but also provide a light, soft, portable and high-grade wearing. experience. The environmental protection characteristics of elastic fabrics are in line with the current trend of green environmental protection and meet the needs of consumers for environmentally friendly products.

8. Adjust the weaving process to create fabric jacquard style.

English

English 中文简体

中文简体 Español

Español 日本語

日本語