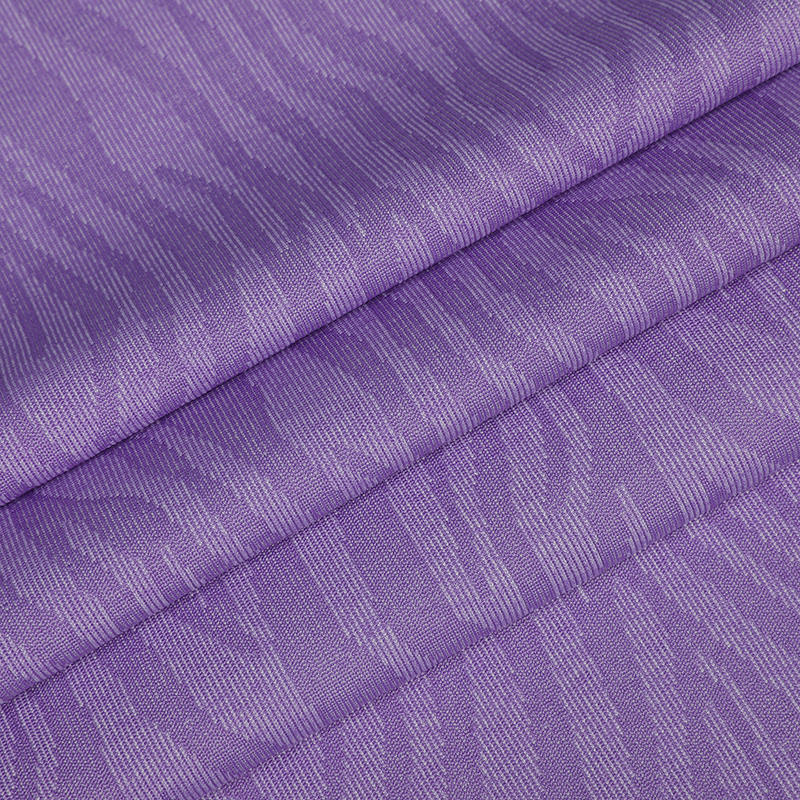

APJ1012 Warp knitted fabric with jacquard gradient blending

APJ1012 warp knitted jacquard gradient strip knitted fabric uses three high-performance fibers, N/NT/OP. Through the precise 44/44/12 yarn ratio, the fabric structure is optimized and the performance is significantly improved.

Gradient yarn stitching technology: We use advanced yarn stitching technology to skillfully blend yarns of different glossiness and fineness to form a natural and smooth gradient effect. This technology not only enriches the color levels of fabrics, but also enhances the visual impact. It provides clothing designers with a broad creative space and meets the market's demand for personalized and differentiated products.

Advantages of warp knitting structure: APJ1012 is woven using warp knitting technology, which gives the fabric elasticity and recovery. This structure allows the fabric to quickly return to its original shape after being subjected to external force, maintaining the stiffness and fit of the garment. It is especially suitable for making garments that require high elasticity and good shape retention, such as sportswear, tights, etc.

High-quality fiber raw materials: We select high-quality fiber raw materials that meet international environmental protection standards to ensure that the fabrics are non-toxic, harmless and skin-friendly. At the same time, these raw materials also have good air permeability and hygroscopicity, which help regulate the human body's microclimate and improve wearing comfort.

Wear resistance and durability: Through scientific yarn ratio and weaving process, APJ1012 fabric shows wear resistance and pilling resistance. This means that the clothing can still maintain its original beauty and texture after being worn for a long time or washed multiple times, extending the service life of the product.

Specifications and applicability: The specifications of this product are 65"/67"*170GSM, which is suitable for a variety of clothing styles and occasions. Its unique gradient effect and good physical properties make APJ1012 an ideal choice for the fashion and sports fields.

1. Polyester fiber fabric has better stiffness than other materials (such as cotton, nylon, etc.).

2. Polyester fabrics are known for their unique elasticity and comfort, and this fabric does not rely on spandex to achieve elasticity.

3. Mechanical elastic fabric can produce a large retraction force when stretched, and maintain the original flat, fluffy and crisp state.

4. Polyester fiber fabric has waterproof performance and fast drying effect, and it is often used as the main ingredient in outdoor sports clothing.

5. Elastic fabrics are more suitable for fitness wear, running wear and dancewear than other ordinary fabrics or chemical fiber fabrics, but also require support and tight degree of demand for high scenes.

6. elastic fabric also has good moisture absorption and quick drying performance. Its double helix structure presents an eight-figure groove section, and its moisture absorption and quick drying property is 8 times higher than that of cotton and two times higher than that of ordinary polyester. This characteristic makes mechanical elastic fabric one of the ideal casual wear main fabrics, to meet the market demand for fast moisture absorption and rapid drying.

7. Under the background of environmental protection becoming a new pursuit, elastic fabric has overcome many shortcomings of spandex elastic fabric and become one of the main choice of casual wear fabrics. Its ammonia-free properties not only reduce environmental pollution, but also provide a light, soft, portable and high-grade wearing. experience. The environmental protection characteristics of elastic fabrics are in line with the current trend of green environmental protection and meet the needs of consumers for environmentally friendly products.

8. Adjust the weaving process to create fabric jacquard style.

English

English 中文简体

中文简体 Español

Español 日本語

日本語